Harley Davidson Exhaust Bolt Torque

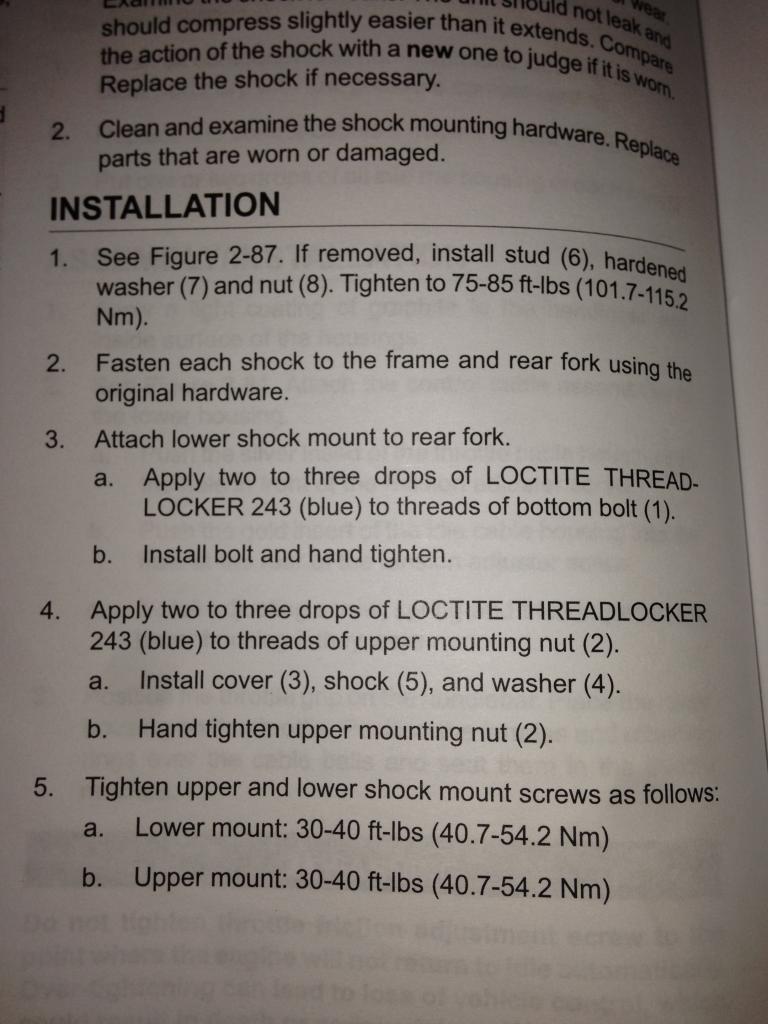

Additionally tighten the head pipe support bracket bolts as indicated in the exhaust manufacturers instructions.

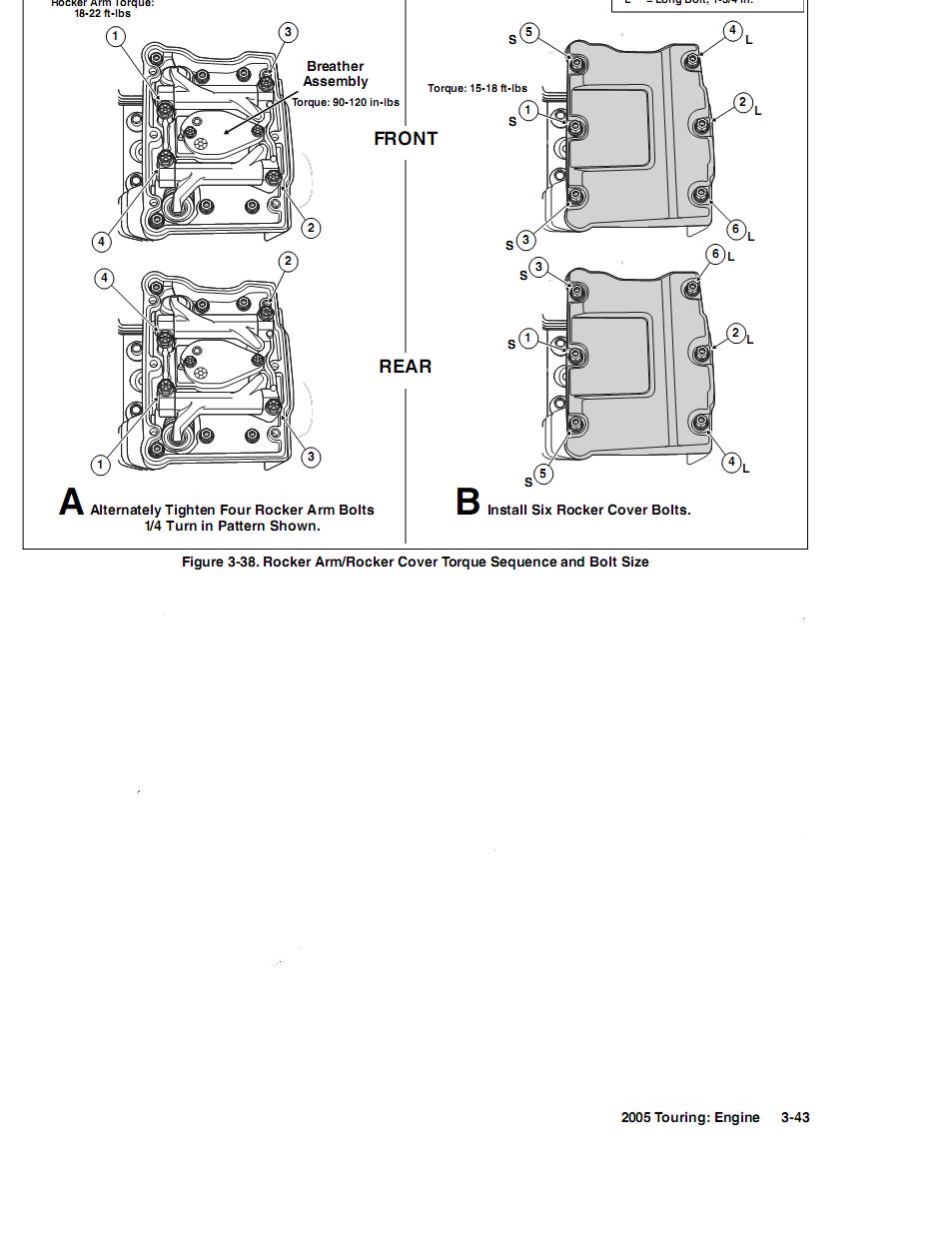

Harley davidson exhaust bolt torque. Tighten the top nut of the front cylinder head exhaust flange to 9-18 in-lbs 1-2 Nm then tighten the bottom nut to 100-120 in-lbs 113-136 Nm final tighten the top nut to 100-120 in-lbs 113-136Nm then tighten the bottom nut of the rear cylinder head exhaust flange to 9-18. The nfieldgear catalog says the correct torque is 4 ftlbs 48 inlbs. Axle nut is set at 50 FOOT lbs.

I hope I explained this where you can understand this. 96 - 120 lbs. Fastener Size - Torque ft.

85 cc bathtub Cam system - Twin cams chain driven with spring loaded tensioners Max. The torque values I found for that size thread gives 8 ftlbs for a steel to steel interface. If you are referring to the cylinder head exhaust flange --- tighten the top nut of the front head to 9-18 in-lbs then tighten the lower nut to 120 in-lbs finally tighten the top nut to 120 in-lbs.

Torque Specs Harley Exhaust Flange. Insert the small end of a torque cone into each of the two exhaust pipe openings until the flange on the cones comes against the flange on the exhaust pipes. Front Intake is Yellow.

Hi all How much torque is required for the nuts on head pipe flange. Youll now want to lower the exhaust pipes until you see the exhaust pipe opening on your Harley-Davidson motorcycle. Expert Gear Advice From Riders.

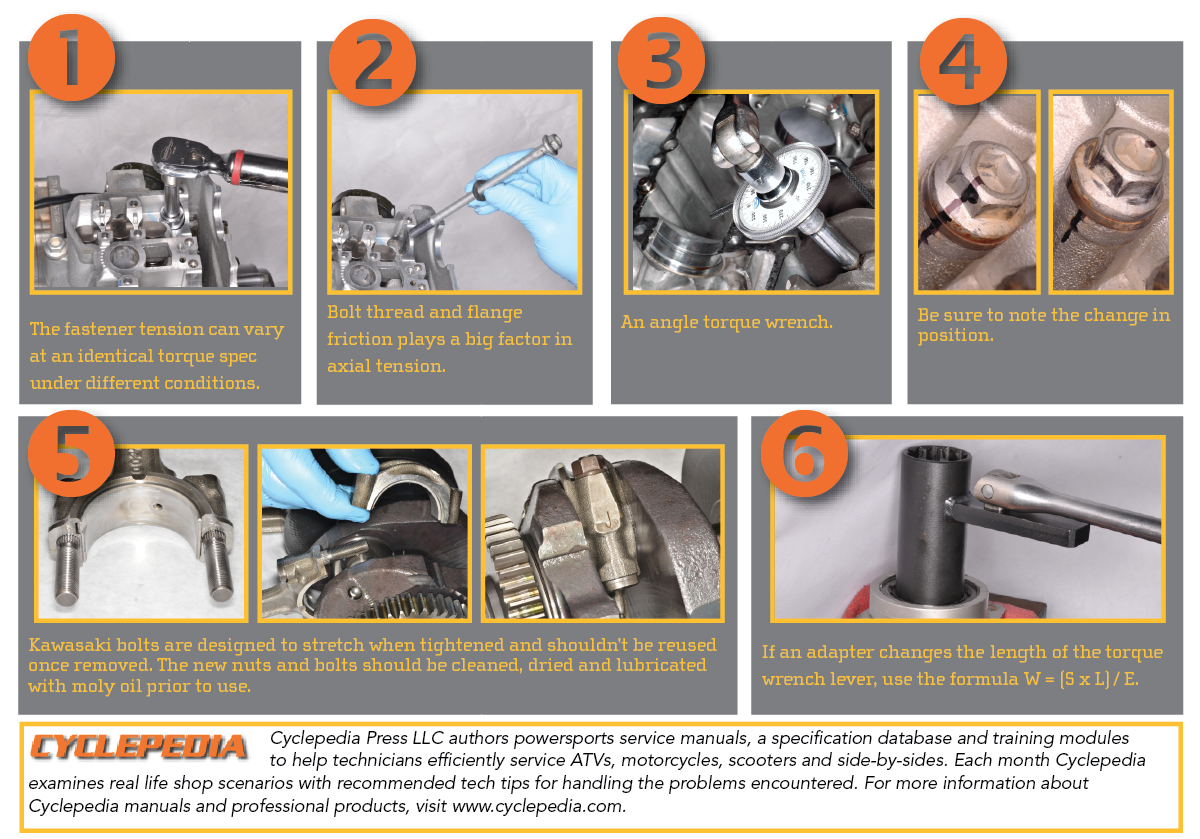

Please could somebody do me a big favour and post up the torque setting for the bolts that hold the exhaust to the motors head. You get a feel for the torque by taking a torque wrench and turning to the specified torque on something else to get the feel for the specified torque. Harleys head-bolt torque method harkens back to a time when torque specifications were less scientific.